Mechanical Properties of Engineering Materials

For various engineering applications the selection of materials so much depends on the properties of materials. For a design engineer without the knowledge of the properties of materials it will be difficult to design. The mechanical properties of materials are the behaviour of the material under various kinds of forces.

Mechanical Properties of Engineering Materials:

For various engineering applications the selection of materials so much depends on the properties of materials. For a design engineer without the knowledge of the properties of materials it will be difficult to design.

The mechanical properties of materials are the behaviour of the material under various kinds of forces. Let us study some important mechanical properties of the engineering materials.

- Strength

- Elasticity

- Plasticity

- Stiffness

- Resilience

- Toughness

- Malleability

- Ductility

- Brittleness

- Hardness

- Fatigue

- Creep

1.Strength

Strength is defined as the ability of the material to resist the external forces without rupture or yielding.

Depending upon the various types of stresses induced by the various kind of external forces strength is also expressed as tensile strength, compressive strength and shear strength, etc.

When an external force is applied on the material different stresses are induced in the material.

Stress is the resistance offered by the material when an external force is applied.

There are tensile stress, compressive stress and shear stress.

When the external force is axial and it pulls the body towards outer then the resistance offered by the body to resist that force is called tensile stress.

When the external force is axial and it compresses the body towards inner then the resistance offered by the body to resist that force is called compressive stress.

Shear stress is the resistance offered by the body to resist the shear force.

Tensile strength, compressive strength and the shear strength are the resistance offered by the body without fracture or yielding when the tensile force, the compressive force and the shear force applied to the body respectively.

2.Elasticity

Elasticity is defined as the ability of the material to regain its original shape and size from deformation when the external forces which caused deformation are removed.

In common engineering applications mostly steel is used due to its high elasticity as well as strength.

3.Plasticity

Plasticity is defined as the ability of the material to retain the deformation permanently caused when the external force is applied. The deformation prolongs permanently even after the external forces are removed.

4.Stiffness

Stiffness is defined as the ability of the material to resist the deformation when the external force is applied. Stiffness is also called rigidity. The value of stiffness is called the modulus of elasticity. Its unit is N/mm2.

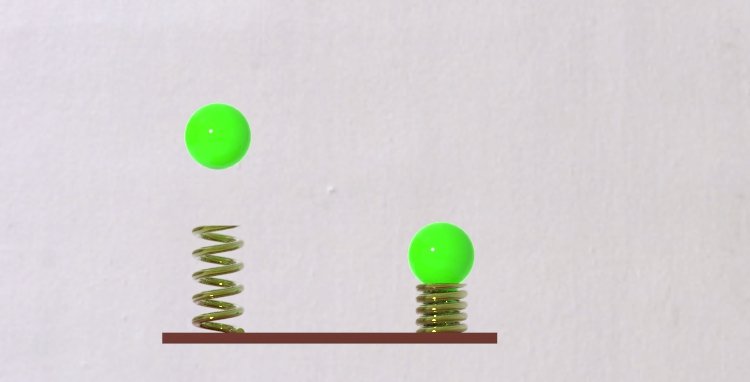

5.Resilience

Resilience is defined as the ability of the material to absorb the energy resisting the shock and impact loads when applied and release this energy when the loads are removed. The measurement of the resilience is called the modulus of resilience. This property is desirable for various types of springs.

6.Toughness

Toughness is defined as the ability of the material to resist the fracture when the external force is applied. The loads are mainly impact loads. The material having more toughness withstands impact loads without fracture. The measurement of toughness is called the modulus of toughness.

7.Malleability

Malleability is defined as the ability of the material to resist the crack with more deformation when the impact force or compressive force is applied. The deformation takes place at the great extent but the crack will not happen earlier. This deformation without crack is so useful in the application of materials which require rolling, forging and extrusion. These materials withstand the blow of hammer.

Malleability is also defined as the property of the material which can be rolled or hammered into sheets.

8.Ductility

Ductility is defined as the ability of the material to resist the crack with more deformation when the tensile force is applied.

It is also defined as the property of the material which can be drawn into wires.

Ductile materials are used in the application of materials which require forming, bending and drawing.

9.Brittleness

Brittleness is defined as the ability of the material not to deform more before fracture when the external force is applied. The plastic deformation is negligible in brittle materials. It is opposite to ductility. Henceforth, brittle materials cannot withstand tensile and fail or fracture suddenly.

Cast iron is an example of brittle material. Brittle materials can withstand compressive force.

10.Hardness

Hardness is defined as the ability of the material to resist wear, scratch, penetration or any permanent deformation.

Hard materials can be used to cut other materials. They can be used in the applications where one material will rub other material. For instance, in cam and follower the follower will rub the cam and move by the direction of cam.

11.Fatigue

Fatigue is the property of the material to fail when it is subjected to repeated stresses.

12.Creep

Creep is the property of the material to deform slowly and permanently when it is subjected to constant stresses at high temperatures for a long period of time.

Are you interested to know about stress and strain? Click the link below

What's Your Reaction?